Sockets Marine Tow Shackles

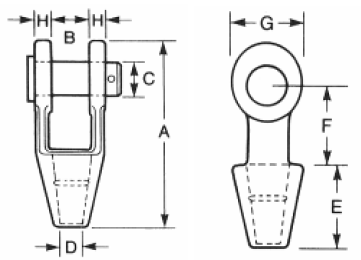

Open Spelter Sockets

|

|||||||||

| Size in Inches | Dimensions in Inches | Weight Each in Pounds | |||||||

| A | B | C | D | E | F | G | H | ||

| 5/16 - 3/8 | 4.88 | 0.81 | 0.81 | 0.50 | 2.25 | 1.75 | 1.50 | 0.44 | 1.30 |

| 7/16 - 1/2 | 5.56 | 1.00 | 1.00 | 0.56 | 2.50 | 2.00 | 1.88 | 0.50 | 2.30 |

| 9/16 - 5/8 | 6.75 | 1.25 | 1.19 | 0.69 | 3.00 | 2.50 | 2.25 | 0.56 | 3.80 |

| 3/4 | 7.94 | 1.50 | 1.38 | 0.81 | 3.50 | 3.00 | 2.63 | 0.63 | 6.00 |

| 7/8 | 9.25 | 1.75 | 1.63 | 0.94 | 4.00 | 3.50 | 3.13 | 0.75 | 10.00 |

| 1.00 | 10.56 | 2.00 | 2.00 | 1.13 | 4.50 | 4.00 | 3.75 | 0.88 | 15.50 |

| 1.1/8 | 11.81 | 2.25 | 2.25 | 1.25 | 5.00 | 4.50 | 4.13 | 1.00 | 22.00 |

| 1.1/4 - 1.3/8 | 13.19 | 2.50 | 2.50 | 1.50 | 5.50 | 5.00 | 4.75 | 1.13 | 32.00 |

| 1.1/2 | 15.13 | 3.00 | 2.75 | 1.63 | 6.00 | 6.00 | 5.38 | 1.19 | 46.00 |

| 1.5/8 | 16.25 | 3.00 | 3.00 | 1.75 | 6.50 | 6.50 | 5.75 | 1.31 | 55.00 |

| 1.3/4 - 1.7/8 | 18.25 | 3.50 | 3.50 | 2.00 | 7.50 | 7.00 | 6.50 | 1.56 | 85.00 |

| 2 - 2.1/8 | 21.50 | 4.00 | 3.75 | 2.25 | 8.50 | 9.00 | 7.00 | 1.81 | 125.00 |

| 2.1/4 - 2.3/8 | 23.50 | 4.50 | 4.25 | 2.50 | 9.00 | 10.00 | 7.75 | 2.13 | 165.00 |

| 2.1/2 - 2.5/8 | 25.50 | 5.00 | 4.75 | 2.88 | 9.75 | 10.75 | 8.50 | 2.38 | 252.00 |

| 2.3/4 - 2.7/8 | 27.25 | 5.25 | 5.00 | 3.13 | 11.00 | 11.00 | 9.00 | 2.88 | 315.00 |

| 3 - 3.1/8 | 29.00 | 5.75 | 5.25 | 3.38 | 12.00 | 11.25 | 9.50 | 3.00 | 380.00 |

Hot galvanized. Forged sockets through 1.1/2". Alloy cast steel 1.5/8" and larger.

7/16" - 2.1/2" meet performance requirements of Federal Specification RR-S-550, current revision.

Caution: When attaching spelter sockets to wire rope it is extremely important to follow recommended procedures, such as outlined by the Wire Rope Technical Board. Proper broomingand cleaning of wire rope is important. If resin is used, follow resin manufacturer's specific installation instructions.

Efficiency of spelter socket terminations: 100% of the catalog breaking strength of wire rope. Ratings are based on the

recommended use with 6 X 7, 6 X 19, or 6 X 37, IPS or XIP (EIP), XXIP (EEIP), RRL, FC, or IWRC wire rope.

Closed Spelter Sockets

| Size in Inches | Dimensions in Inches | Weight Each in Pounds | |||||||

| A | B | C | D | E | F | G | H | ||

| 5/16 - 3/8 | 4.88 | 0.94 | 0.63 | 0.5 | 2.25 | 2 | 1.69 | 0.69 | 1.1 |

| 7/16 - 1/2 | 5.44 | 1.13 | 0.69 | 0.56 | 2.50 | 2.25 | 2.00 | 0.88 | 1.50 |

| 9/16 - 5/8 | 6.31 | 1.38 | 0.81 | 0.69 | 3.00 | 2.50 | 2.63 | 1.00 | 3.00 |

| 3/4 | 7.56 | 1.63 | 1.06 | 0.81 | 3.50 | 3.00 | 3.00 | 1.25 | 4.50 |

| 7/8 | 8.75 | 1.88 | 1.25 | 0.94 | 4.00 | 3.50 | 3.63 | 1.50 | 7.00 |

| 1 | 9.88 | 2.25 | 1.38 | 1.13 | 4.50 | 4.00 | 4.13 | 1.75 | 11.00 |

| 1.1/8 | 11.00 | 2.50 | 1.50 | 1.25 | 5.00 | 4.50 | 4.50 | 2.00 | 16.00 |

| 1.1/4 - 1.3/8 | 12.13 | 2.75 | 1.63 | 1.50 | 5.50 | 5.00 | 5.00 | 2.25 | 22.00 |

| 1.1/2 | 13.94 | 3.13 | 1.94 | 1.63 | 6.00 | 6.00 | 5.38 | 2.50 | 28.00 |

| 1.5/8 | 15.38 | 3.25 | 2.13 | 1.75 | 6.50 | 6.75 | 5.75 | 2.75 | 36.00 |

| 1.3/4 - 1.7/8 | 17.25 | 3.53 | 2.19 | 2.00 | 7.50 | 7.56 | 6.75 | 3.00 | 58.00 |

| 2 - 2.1/8 | 19.50 | 3.78 | 2.44 | 2.25 | 8.50 | 8.56 | 7.63 | 3.25 | 80.00 |

| 2.1/4 - 2.3/8 | 21.38 | 4.28 | 2.88 | 2.50 | 9.00 | 9.50 | 8.50 | 3.63 | 105.00 |

| 2.1/2 - 2.5/8 | 23.50 | 5.50 | 3.13 | 2.88 | 9.75 | 10.63 | 9.50 | 4.00 | 140.00 |

| 2.3/4 - 2.7/8 | 25.38 | 6.50 | 3.13 | 3.13 | 11.00 | 11.25 | 10.75 | 4.88 | 220.00 |

| 3 - 3.1/8 | 27.00 | 6.75 | 3.25 | 3.38 | 12.00 | 11.75 | 11.50 | 5.25 | 276.00 |

Hot galvanized. Forged sockets through 1.1/2". Alloy cast steel 1.5/8" and larger.

7/16" - 2.1/2" meet performance requirements of Federal Specification RR-S-550, current revision.

Caution: When attaching spelter sockets to wire rope it is extremely important to follow recommended procedures, such as outlined by the Wire Rope Technical Board. Proper broomingand cleaning of wire rope is important. If resin is used, follow resin manufacturer's specific installation instructions.

Efficiency of spelter socket terminations: 100% of the catalog breaking strength of wire rope. Ratings are based on the

recommended use with 6 X 7, 6 X 19, or 6 X 37, IPS or XIP (EIP), XXIP (EEIP), RRL, FC, or IWRC wire rope.

Marine Tow Shackles

| Work Load | Size | Jaw Width | Width Bow | Inside Length | Pin | Weight |

| 30T | 1-3/4 | 5.00 | 7.00 | 9-3/4 | 2.00 | 43 lbs |

| 40T | 2.00 | 5-3/4 | 7-1/2 | 10.00 | 2-1/4 | 59 lbs |

| 55T | 1-1/2 | 6-1/4 | 8.00 | 10-1/4 | 2-3/4 | 100 lbs |